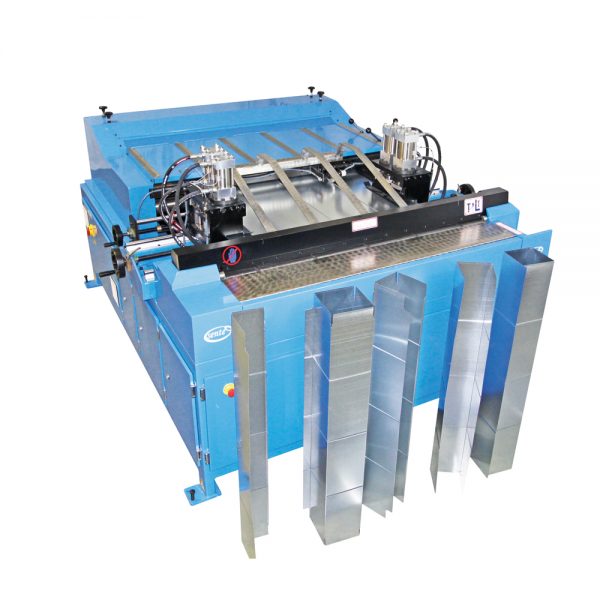

This machine and Auto Duct Forming machine has the same characteristics. In addition; it makes ducts with notching.

Auto duct forming machine with notching system has a punch system more than Standard Auto Duct Forming Machine.The machine can be arranged for both slip on flange TDF/TDC self flange or S&Cleat. This unit is designed hydraulic pump and four items of hydraulic cylinders (two items are in one side, two items other side)

It perforates appropriate thin plate to the twist point in desired coordinates (dimensions entered from screen). Notching stations can be adapted manually at the side of right and left according to width of sheet. Punch dimensions can be changes for different flanges.

Product Description

| POWER | 6,5 KW |

| VOLTAGE – FREQUENCY | 380/400 VAC / 50 – 60 Hz / 3Ph+PE |

| CURRENT | 15 A |

| AIR CONSUMPTION | N/A |

| HYDRAULIC SYSTEM | YES |

| LUBRICATION | Automatic |

| FEEDING SPEED | 6 m/min |

| MINIMUM DUCT SIZE | Min. 125 x 125 mm |

| TYPE OF BENDING DUCT | L Type ‘ U Type ‘ Full Duct ‘ Straight Sheet |

| SEAM TYPES | Pittsburgh, Snaplock, Nulock |

| UNCOILER CAPACITY | İnner dia. Ø 508 mm

Max. width 1500 mm max. 5 ton |

| THICKNESS RANGE OF THIN PLATE | 0,5 – 1,25 mm Galvanized, Aluminium

0.5 – 0.80 mm Stainless Steel.

|

| DIMENSIONS | 7,3 m x 2,2 m |

| WEIGHT | 3610 kg (7958 POUNDS) |

| DESIGN CYLINDER | Z Design |

| OPTIONS | Double design cylinder (Z + trapez profile)

U Beading Sente form Automatic labelling system Operating voltage (220V, 380V, 460V) |